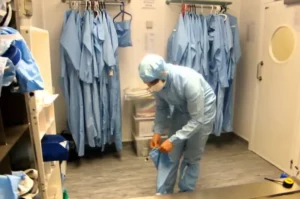

In a pharmaceutical manufacturing industry, working with biological materials is a fairly common practice. These materials may or may not be hazardous to the worker, but they can most certainly be sensitive to microbiological contaminants. Contamination is mostly originated by a personnel. It is important to use proper, germfree cleanroom garments in order to protect the products and the personnel from contamination. Researchers come in direct contact with various products, substance or material through their hands and hence, need to be protected from exposure to chemicals. This is where cleanroom gloves come into the picture. Various types of cleanroom gloves are used for various purposes and a certain type of cleanroom gloves must be used for a certain material.

As a contamination-free environment leads to quality sterilization and prevents infections, Autoclaving is considered as the most effective and reliable sterilization method. Autoclave sterilization uses high pressure and high temperature steam to kill microorganisms and render bio hazardous material inactive. High-pressure heat, steam burns, hot fluid scalds, injuries to hands and arms from the door, and bodily injury in the event of an explosion are potential risks of using autoclaves. This becomes imperative for any pharmaceutical personnel to use appropriate Personal Protective Equipment (PPE) including autoclavable gloves and gauntlets.

Let’s now understand the varied types of materials used while manufacturing autoclavable pharmaceutical gauntlets with studying their high-protection benefits.

1. Ethylene Propylene Diene Monomer (EPDM)

Ethylene Propylene Diene Monomer or EPDM possess an excellent resistance to environmental factors like Ozone, UV and general weathering at higher temperatures that reaches maximum at 130°C (266°F). EPDM infused Autoclavable Gauntlets carry a high level of resistance to abrasion, solvents and perforation. The use of heat-insulating gloves helps and prevents burns while loading and unloading autoclave. Suffused with hydrogen peroxide, these gloves provide anti- septic for cuts and burns due to handling autoclaves or any high temperature material.

2. Hypalon

Hypalon is made up of man-made rubber called CSM or chlorosulfonated polyethylene, generally fabric-coated that resists abrasion, UV rays and chemical very efficiently. Pharmaceutical gauntlets made of hypalon material are soft, flexible specially designed for high convenience. Hypalon Gauntlets possess high resistance against hydrogen peroxide and hence suitable for autoclaving.

3. Neoprene

Also known as polychloroprene, neoprene is a kind of synthetic rubber made of polymerization of chloroprene. This material possess excellent chemical resistance and maintains flexibility over a wide temperature range. Neoprene Gauntlets give outstanding protection against heavy duty, abrasions and cut objects during autoclaving. These gauntlets are warm and feels good to wear in all the seasons.

4. Nitrile

Nitrile is a medical-grade material in terms of pharmaceutical gauntlets. Nitrile is resistant to aliphatic hydrocarbons and it carries a high level of resistance to abrasion, solvents and perforation. Nitrile Gauntlets are manufactured from accelerator free nitrile with low levels of particles. They can be easily sanitized with VHP or IPA with being suitable for autoclaving.

At June Enterprises, our pharmaceutical industry experts deliver the one-stop solutions for all your pharmaceutical discomfort and problems. We owe to serve you the best and so you can always feel free to seek our assistance and ease out your autoclaving process.